CNC Material

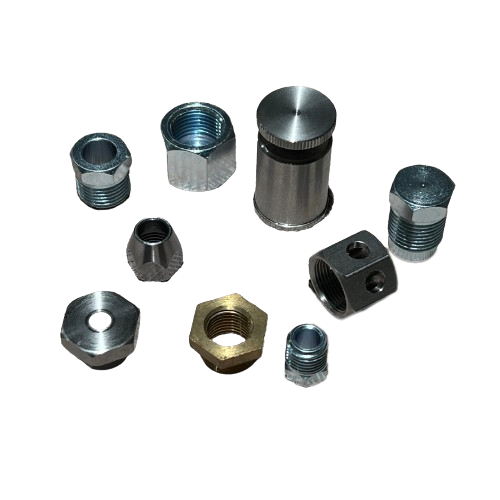

CNC machining can work with a wide range of materials, including metals (such as aluminum, steel, brass, and titanium), plastics, wood, and composites. The choice of material depends on the specific application and requirements of the product.

Steel: This is the most commonly used material in CNC manufacturing due to its strength, durability, and affordability. It can be used for a wide range of applications, including automotive parts, appliances, and construction materials.

Aluminum: Aluminum is lightweight, corrosion-resistant, and has a high strength-to-weight ratio, making it a popular choice for stamping manufacturing in the aerospace, automotive, and electronics industries.

Copper: Copper is a highly conductive and corrosion-resistant material that is commonly used for electrical and plumbing applications.

Brass: Brass is a durable and corrosion-resistant alloy of copper and zinc that is commonly used for decorative items, as well as plumbing and electrical components.

Products

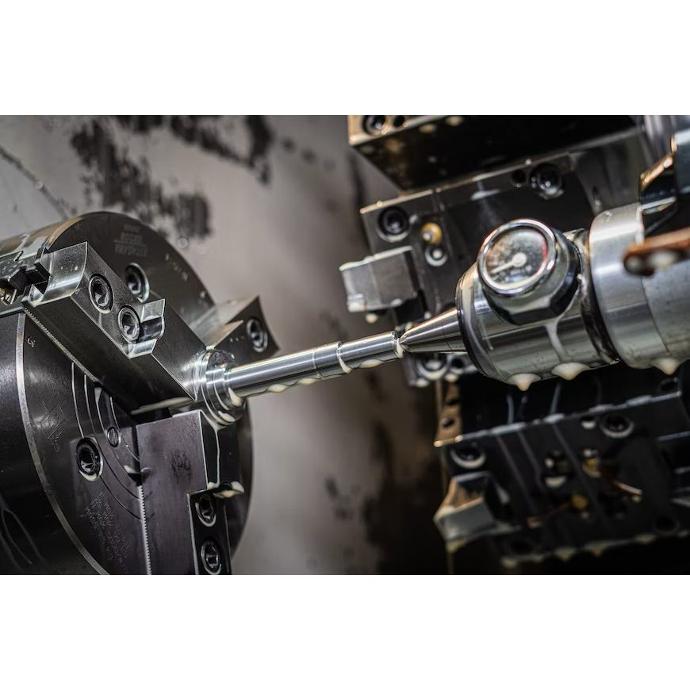

CNC machining can be used to make a wide range of products, including but not limited to:

Aerospace components, such as engine parts and landing gear

Automotive parts, such as engine blocks and cylinder heads

Medical devices, such as implants and surgical instruments

Electronics components, such as heat sinks and enclosures

Consumer products, such as phone cases and computer parts

Prototypes and custom parts for various industries

In general, CNC machining is a versatile manufacturing process that can be used to create complex and precise parts for a variety of applications.