Metal Sheet Manufacturing

Using a press and dies to transform flat sheet metal into a variety of complex shapes, such as stamping, laser cuting and bending,

Stamping

Stamping manufacturing is a process that uses stamping presses and dies to transform flat sheet metal into a variety of complex shapes. The process involves using a machine press to apply pressure to a sheet of metal, forcing it into a die to create a specific shape or cut. The process is commonly used to create parts for a wide range of products, from small electronic components to large automotive parts. The benefits of stamping manufacturing include high accuracy, repeatability, and efficiency, which can lead to cost savings and improved product quality.

Material and Products

Stamping is a metalworking process that involves pressing or punching a flat sheet of metal into a desired shape. The type of material and product that is suitable for stamping manufacturing will depend on the specific requirements of the project.

Some common materials used in stamping manufacturing include:

Steel: This is the most commonly used material in stamping manufacturing due to its strength, durability, and affordability. It can be used for a wide range of applications, including automotive parts, appliances, and construction materials.

Aluminum: Aluminum is lightweight, corrosion-resistant, and has a high strength-to-weight ratio, making it a popular choice for stamping manufacturing in the aerospace, automotive, and electronics industries.

Copper: Copper is a highly conductive and corrosion-resistant material that is commonly used for electrical and plumbing applications.

Brass: Brass is a durable and corrosion-resistant alloy of copper and zinc that is commonly used for decorative items, as well as plumbing and electrical components.

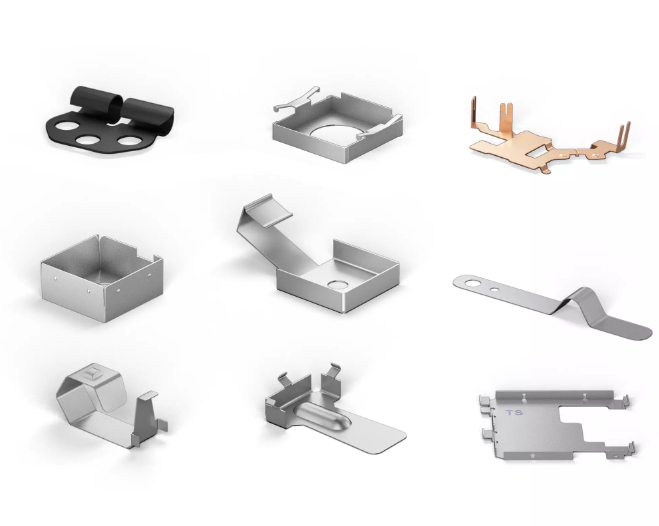

Products

Automotive parts: Stampings are used to manufacture a wide range of automotive components, including body panels, brackets, and chassis components.

Electronic components: Stampings are commonly used to produce electronic components such as connectors, terminals, and contact plates.

Appliances: Many appliance components are manufactured using stamping, including oven racks, refrigerator shelves, and washing machine parts.

Aerospace components: Stamping is used to produce a wide range of aerospace components, including structural components, brackets, and fittings.

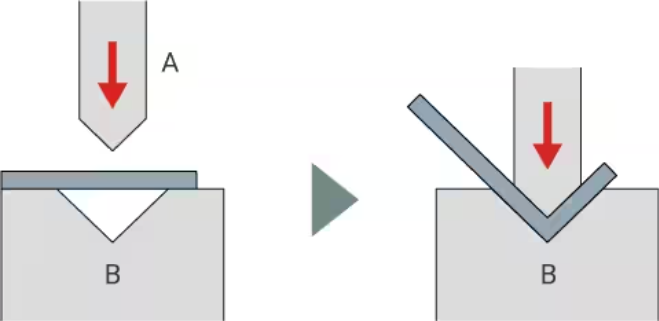

Bending Press

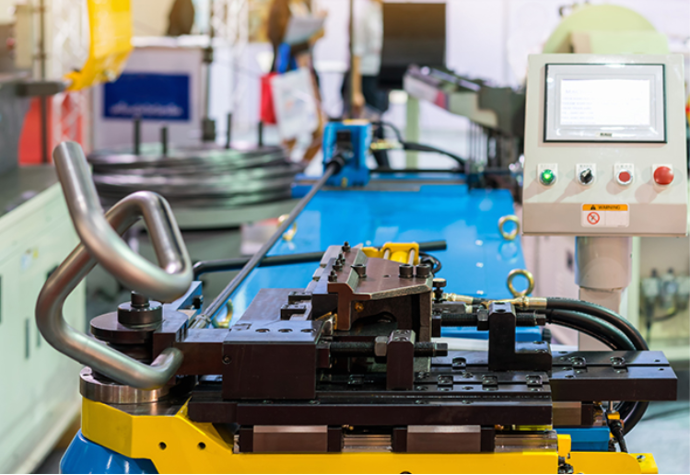

A bending press, also known as a press brake, is a machine tool used in metalworking to bend and shape metal sheets into various shapes and angles. It is commonly used in industries such as automotive manufacturing, aerospace, construction, and metal fabrication.

The basic components of a bending press include a frame, a hydraulic or mechanical ram, a bending die, and a back gauge. The frame of the press is typically made of steel and provides a stable foundation for the machine. The ram is the moving part of the press that applies the bending force to the metal sheet. The bending die is a shaped tool that is mounted onto the ram and used to form the metal sheet into the desired shape. The back gauge is an adjustable stop that helps ensure accurate and consistent bending of the metal sheet.

Bending CNC

The bending process involves positioning the metal sheet on the bed of the press, which is typically a flat surface. The back gauge is adjusted to the desired position, and the ram is then lowered onto the metal sheet, applying a bending force to the sheet. The metal sheet is then bent to the desired angle or shape by the bending die. The back gauge can be adjusted between bends to ensure that each bend is made at the correct location.

Bending presses come in various sizes and configurations, with some capable of bending metal sheets up to several meters in length and several millimeters in thickness. They can also be operated manually or through computer numerical control (CNC) programming, which allows for greater precision and accuracy in the bending process.

Overall, bending presses are an essential tool in metalworking, providing a reliable and efficient method for bending and shaping metal sheets into a wide range of shapes and angles.